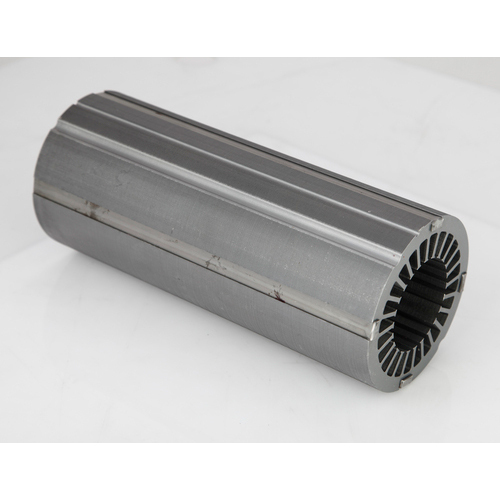

DC Motor Stamping

Product Details:

- Product Type DC Motor Stamping

- Material CRNO (Cold Rolled Non Oriented steel)

- Surface Treatment Zinc Plated/Polished

- Voltage 12-24 V

- Gross Power Depend on Application

- Size Standard & Customized

- Color Silver Grey

- Click to View more

X

DC Motor Stamping Price And Quantity

- 1 , , Ton

DC Motor Stamping Product Specifications

- Zinc Plated/Polished

- CRNO (Cold Rolled Non Oriented steel)

- 30-200 g

- Silver Grey

- DC Motor Stamping

- Customized

- 12-24 V

- Depend on Application

- Standard & Customized

DC Motor Stamping Trade Information

- 500-800 , , Ton Per Month

- 15 Days

Product Description

PMDC Motor Stamping

Outer Diameter: 80.50 MM

Inner Diameter: 20.530 MM

Slots: 18 Nos.

We are reckoned as a one of the distinguished manufacturers, traders, exporters and suppliers of quality approvedAlternator Electrical Stamping. This stamping is fabricated using high grade raw materials acquired from trusted vendors of the market.Our offeredAlternator Electrical Stampingis broadly known for robust construction, corrosion resistance, high tensile strength, easy installation and elevated service life. Considering the broad needs of the clients, we offer this product in various specifications at an acceptable price range.

Precision and Performance

These DC motor stampings are meticulously crafted to ensure high efficiency and reliability. The use of soft magnetic CRNO steel and progressive stamping allows for tight tolerances and optimal magnetic properties, making them ideal for demanding electric motor applications.

Customization and Versatility

Our stampings can be tailored to your specifications, including dimensions, mounting holes, surface treatments, and voltage ratings. Whether you require standard sizes or unique configurations, our products can accommodate your exact requirements for automotive, appliance, or industrial use.

Durability and Corrosion Resistance

Finished with a zinc plating or polished surface, these stampings boast excellent corrosion resistance. This quality extends the lifespan of motor components and ensures dependable operation, even in challenging environments.

FAQs of DC Motor Stamping:

Q: How are DC motor stampings manufactured for electric motors and appliances?

A: DC motor stampings are produced using progressive stamping techniques, which provide precise shapes and dimensions. This process ensures each stamping maintains the specified tolerance and magnetic softness, enhancing performance for electric motors, automotive applications, and appliances.Q: What materials are used for these stampings and why are they important?

A: We use CRNO (Cold Rolled Non Oriented steel) for all our stampings. This material is chosen for its superior soft magnetic properties, essential for efficient motor operation, and for its corrosion resistance, boosting durability in diverse environments.Q: When should customized dimensions and mounting options be considered?

A: Customized dimensions and mounting holes are recommended when standard sizes do not fit your application or when specific installation requirements need to be met, ensuring optimal performance and compatibility with your motor design.Q: Where are these DC motor stampings commonly applied?

A: Our stampings are broadly used in electric motors, automotive systems, and household appliances across various industries in India, with flexible sizing to meet specific market needs.Q: What benefits do progressive stamping and tight tolerances offer?

A: Progressive stamping enables consistent production of stampings with tight tolerances (0.01 mm), improving magnetic efficiency and reducing energy losses in motor applications. This precision ensures reliable operation in every environment.Q: How does surface treatment contribute to the products longevity?

A: Surface treatments such as zinc plating or polishing enhance corrosion resistance, protecting the stampings from rust and wear over time, thereby increasing the longevity and reliability of your motor assemblies.Q: What voltage ranges and weights are available for these stampings?

A: The stampings support voltage options from 12-24 V and weigh between 30-200 g, with all specifications fully customizable based on application requirements, ensuring suitability for both standard and specialized uses.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email