Call Us : 08045801213

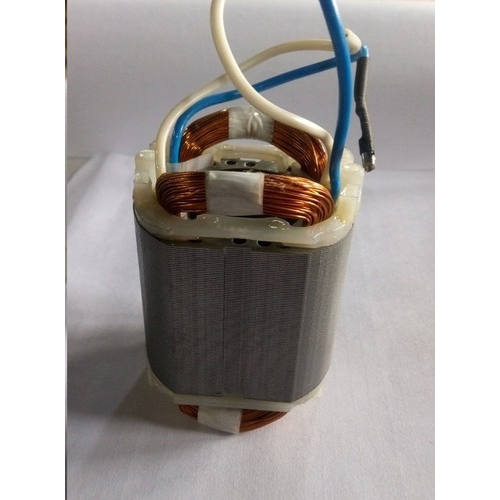

Copper Field Coil Stamping

Product Details:

- Product Type Field Coil Stamping

- Material Copper

- Surface Treatment Electroplated

- Voltage 220-440 V

- Gross Power Based on application

- Size Customized

- Color Copper

- Click to View more

X

Copper Field Coil Stamping Price And Quantity

- 1 Ton

Copper Field Coil Stamping Product Specifications

- Field Coil Stamping

- Copper

- As per requirement

- Variable

- Based on application

- Customized

- Copper

- Electroplated

- 220-440 V

Copper Field Coil Stamping Trade Information

- Per Month

- 15 Days

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

Copper field coil stamping refers to the process of manufacturing stamped copper coils used in electromagnetic devices such as motors, generators, and transformers. Field coils are an essential component in these devices, generating a magnetic field that interacts with other parts to enable the desired functionality. Copper field coil stamping involves precision cutting and shaping of copper sheets to create coil windings that provide efficient and reliable electromagnetic performance.

Frequently Asked Questions :

Q: What is copper field coil stamping?

A: Copper field coil stamping is the process of manufacturing stamped copper coils used in electromagnetic devices. It involves cutting and shaping copper sheets into coil windings that generate the magnetic field necessary for the operation of motors, generators, and transformers.

Q: Why is copper used for field coil stamping?

A: Copper is a preferred material for field coil stamping due to its excellent electrical conductivity and high thermal conductivity. It allows for efficient energy transfer and minimizes heat buildup, resulting in improved overall performance and reliability.

Q: What are the applications of copper field coil stampings?

A: Copper field coil stampings find application in various electromagnetic devices such as electric motors, generators, transformers, and solenoids. They are used in industries ranging from automotive and aerospace to power generation and industrial machinery.

Q: How are copper field coil stampings manufactured?

A: Copper field coil stampings are typically manufactured through a process of die stamping. Copper sheets or strips are fed through a die, which cuts and shapes them into the desired coil windings. The stampings are then further processed and assembled into the final device.

Precision-Engineered for Superior Performance

Our copper field coil stamping components are crafted to meet precise tolerances, resulting in dependable and consistent operation. Each piece undergoes electroplated surface treatment for a smooth finish and enhanced durability. Designed to support various voltage requirements, these stampings can be custom-sized to accommodate specific applications in electric motors and generators.

Versatile Applications Across Industries

Suitable for an array of electric motor and generator types, our copper field coil stampings offer excellent adaptability. Their enamel-coated insulation and corrosion-resistant properties ensure long-term performance, even in demanding environments. We offer full support for custom shapes and sizes, making them ideal for diverse industry requirements.

FAQs of Copper Field Coil Stamping:

Q: How is the copper field coil stamping manufactured and what makes the process reliable?

A: The copper field coil stamping is produced through a precise stamping process, utilizing advanced machinery to achieve a tolerance of 0.01 mm. This reliable method ensures each piece meets IS 6362 standards and maintains uniformity in shape and size, essential for electric motor and generator applications.Q: What are the main applications of these copper field coil stampings?

A: These stampings are primarily used in electric motors and generators. Their customizable dimensions and robust enamel insulation make them suitable for a wide range of industrial and commercial applications where efficient electrical conduction and durability are essential.Q: When should I consider customizing the size or shape of the field coil stamping?

A: Custom sizing or shaping is ideal when you need the stamping to fit specific motor or generator designs that fall outside standard dimensions. Customized options ensure optimal compatibility, efficient performance, and integration into your unique assembly requirements.Q: Where can these copper field coil stampings be supplied from and who can purchase them?

A: We supply these stampings throughout India, serving as a dealer, distributor, exporter, manufacturer, retailer, supplier, and wholesaler. Industries, OEMs, and maintenance companies can easily source these products according to their specifications.Q: What are the benefits of using enamel-coated copper field coil stampings with electroplated surfaces?

A: The enamel coating enhances insulation and electrical safety, while the electroplated surface provides a smooth texture and superior corrosion resistance. Together, these features improve product longevity and reduce maintenance needs in high-performance environments.Q: How are the field coil stampings used within electric motors and generators?

A: They form a crucial component of the electromagnetic field system inside motors and generators, facilitating efficient current flow with minimal energy loss. Their specific rectangular or custom shapes enable tailored fits for different designs, improving overall machine efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email