Industrial Electrical Motor Stamping

Product Details:

- Product Type Electrical Motor Stamping

- Material High-grade Silicon Steel

- Surface Treatment Anti-rust coating / Zinc Plated

- Voltage 220-440 V

- Gross Power As per application

- Size Standard and Customized sizes available

- Color Grey/Silver

- Click to View more

X

Industrial Electrical Motor Stamping Price And Quantity

- 1 Ton

Industrial Electrical Motor Stamping Product Specifications

- Customized as per requirement

- High-grade Silicon Steel

- Grey/Silver

- Anti-rust coating / Zinc Plated

- As per application

- Electrical Motor Stamping

- 220-440 V

- Standard and Customized sizes available

- Varies with size and thickness

Industrial Electrical Motor Stamping Trade Information

- 500-800 Ton Per Month

- 15 Days

Product Description

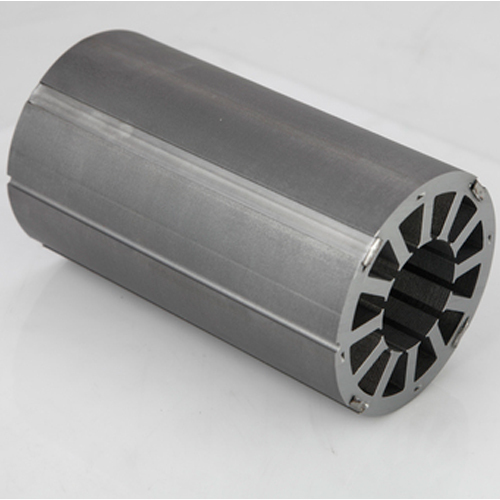

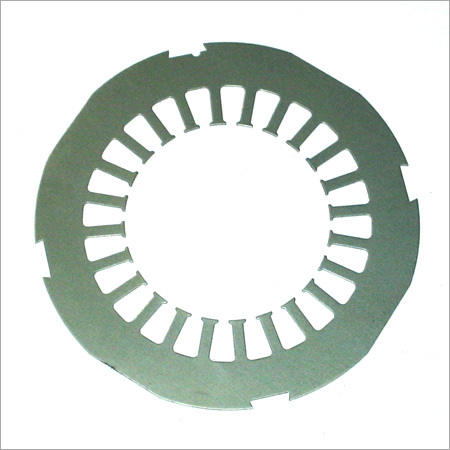

PMDC Motor Stamping

Outer Diameter: 92 MM

Inner Diameter : 42 MM

Slots: 12 Nos.

We are reckoned as a one of the distinguished manufacturers, traders, exporters and suppliers of quality approvedAlternator Electrical Stamping. This stamping is fabricated using high grade raw materials acquired from trusted vendors of the market.Our offeredAlternator Electrical Stampingis broadly known for robust construction, corrosion resistance, high tensile strength, easy installation and elevated service life. Considering the broad needs of the clients, we offer this product in various specifications at an acceptable price range.

Precision Craftsmanship for Demanding Applications

Utilizing progressive die stamping, our motor stampings achieve precise dimensions and high-quality finishes. The edges are always smooth and burr-free, supporting reliable performance in industrial motors, pumps, and generators. We offer both standard and customized sizes to match the unique needs of any project.

Superior Material and Surface Protection

Manufactured from premium silicon steel, our stampings provide exceptional electrical and mechanical properties. The treated surfaces, including anti-rust coating or zinc plating, deliver robust corrosion resistance and high thermal stability, ensuring durability even under demanding operational conditions.

Compliance, Customization, and Packing Assurance

Every stamping meets IS, ASTM, and IEC standards for guaranteed quality and reliability. Customizations are available based on client drawings and specifications. Products are securely packed in wooden boxes, cartons, or palletized packages for safe delivery across India.

FAQs of Industrial Electrical Motor Stamping:

Q: How are the industrial electrical motor stampings produced to maintain high precision?

A: Our motor stampings are manufactured through progressive die stamping, which ensures close tolerance, accurate dimensions, and repeatable high-quality results across the entire batch.Q: What shapes and sizes are available for motor stampings?

A: We offer round, slotted, and custom shapes based on drawings, with thicknesses ranging from 0.35 mm to 1.2 mm. Dimensions can be tailored as per the clients requirements.Q: When should I choose customized stampings over standard options?

A: Customized stampings are ideal when you require specific shapes, dimensions, or design features for unique motor, pump, or generator applications not covered by standard products.Q: Where are these stampings typically used and supplied?

A: Our stampings are used in industrial motors, pumps, and generators and are distributed throughout India to dealers, distributors, exporters, manufacturers, retailers, suppliers, and wholesalers.Q: What benefits do treated surfaces and smooth edges offer?

A: Surface treatments like anti-rust coating and zinc plating enhance corrosion resistance, while smooth, burr-free edges ensure safe handling, easy assembly, and optimal motor efficiency.Q: How is thermal and corrosion resistance achieved in these components?

A: High thermal stability is provided by using annealed or semi-processed silicon steel, and corrosion resistance is ensured through advanced surface treatments and precise manufacturing processes.Q: What packaging methods are used for safe transport and storage?

A: Stampings are packed using wooden boxes, cartons, or pallets, protecting them during transit and storage, and minimizing risk of damage or deformation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email