Call Us : 08045801213

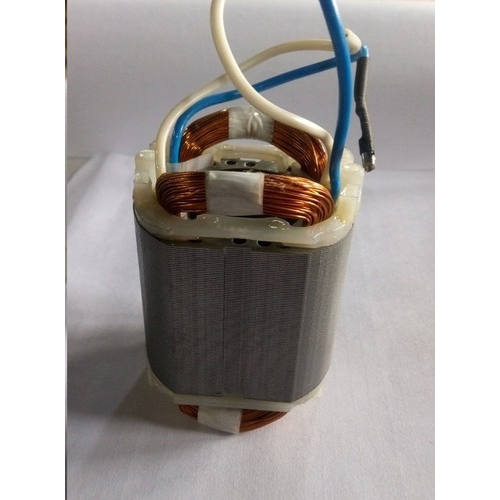

Lamination Stamping

Product Details:

- Product Type Lamination Stamping

- Material Steel

- Color Silver

- Click to View more

X

Lamination Stamping Price And Quantity

- 1 Unit

Lamination Stamping Product Specifications

- Steel

- Silver

- Lamination Stamping

Lamination Stamping Trade Information

- 10 Hours

Product Description

Lamination stamping, also known as laminated core stamping, refers to the process of manufacturing laminations or stampings used in electrical devices such as transformers, motors, generators, and inductors. Lamination stamping involves the precision cutting and stacking of thin layers of electrical steel, often with insulating coatings, to form the core of these devices. This laminated construction reduces energy losses caused by eddy currents, improves magnetic performance, and enhances the efficiency of electrical devices.

Frequently Asked Questions :

Q: What is lamination stamping?

A: Lamination stamping is the process of manufacturing laminated cores or stampings used in electrical devices such as transformers, motors, generators, and inductors. It involves cutting and stacking thin layers of electrical steel with insulating coatings to reduce energy losses and optimize device performance.

Q: Why are laminated cores used in electrical devices?

A: Laminated cores, created through lamination stamping, are used in electrical devices to minimize energy losses caused by eddy currents. The lamination process involves stacking thin layers of steel with insulation between them, which effectively isolates each layer and reduces the formation of eddy currents.

Q: How are laminations stamped?

A: Laminations are typically stamped using high-speed progressive die stamping. This process involves feeding a continuous strip of electrical steel through a series of dies that progressively cut and shape the laminations. The stampings are then separated, cleaned, and further processed for assembly.

Q: What are the benefits of lamination stamping?

A: Lamination stamping offers several advantages. It helps to reduce energy losses, improve magnetic performance, and enhance the efficiency of electrical devices. The laminated construction reduces the impact of eddy currents, resulting in higher efficiency and improved overall device performance

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email