Call Us : 08045801213

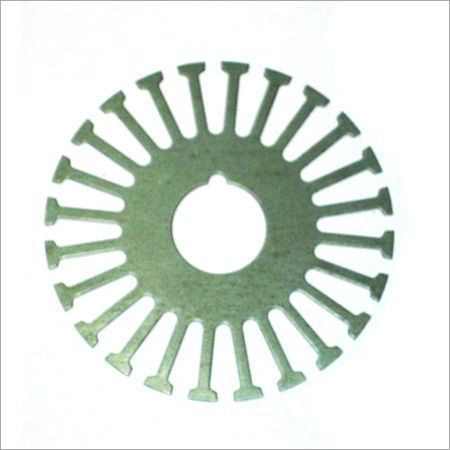

PMDC Motor electricals Stamping

200-3000 INR/Kilograms

Product Details:

- Product Type Electro Stamping

- Material Mild Steel

- Warranty 1 Year

- Click to View more

X

PMDC Motor electricals Stamping Price And Quantity

- 200-3000 INR/Kilograms

- 1 Ton

PMDC Motor electricals Stamping Product Specifications

- Electro Stamping

- Mild Steel

- 1 Year

PMDC Motor electricals Stamping Trade Information

- 500-800 Ton Per Month

- 15 Days

- Yes

- Contact us for information regarding our sample policy

- All India

Product Description

PMDC Motor Electricals Stamping is a vital component in the manufacturing of permanent magnet DC (PMDC) motors. It refers to the process of fabricating laminated steel cores, known as stampings or laminations, which are used as the stator and rotor in PMDC motors. These stampings are carefully designed to ensure efficient electromagnetic performance and minimize energy losses within the motor.

Frequently Asked Questions :

Q: What is PMDC motor electricals stamping?

A: PMDC motor electricals stamping is the process of creating laminated steel cores that form the stator and rotor of a permanent magnet DC motor. These stampings are designed to enhance the motor's electromagnetic properties and minimize energy losses.

Q: Why are laminated steel cores used in PMDC motors?

A: Laminated steel cores, or stampings, are used in PMDC motors to reduce energy losses caused by eddy currents. The lamination process involves stacking thin layers of steel together with insulation, which helps to isolate each layer and prevent the formation of eddy currents.

Q: How are PMDC motor stampings manufactured?

A: PMDC motor stampings are typically manufactured using high-speed progressive die stamping. This process involves feeding a continuous strip of steel through a series of dies that progressively cut and shape the laminations. The stampings are then separated, cleaned, and further processed before assembly.

Q: What factors are considered in designing PMDC motor stampings?

A: The design of PMDC motor stampings takes into account various factors such as magnetic flux distribution, core losses, efficiency, and mechanical stability. These considerations ensure that the stampings provide optimal performance and durability for the motor.

Q: What are the advantages of using stampings in PMDC motors?

A: Using stampings in PMDC motors offers several advantages. They help to reduce energy losses, improve magnetic efficiency, and enhance motor performance. Additionally, stampings allow for easier assembly, better heat dissipation, and overall cost-effectiveness in mass production.

Enter Buying Requirement Details