Call Us : 08045801213

PMDC Motor Rotor Stampings

Product Details:

- Product Type Rotor Stamping for PMDC Motors

- Material CRNGO / CRGO Electrical Steel

- Surface Treatment Phosphated / Oiled

- Voltage 12V / 24V DC

- Gross Power Up to 500W (Depends on application)

- Size Dia 18mm 100mm

- Color Silver Grey

- Click to View more

X

PMDC Motor Rotor Stampings Price And Quantity

- 1 Ton

- As per motor armature design

- Carton box or customized

- Automobile, Home Appliance, Industrial Motors

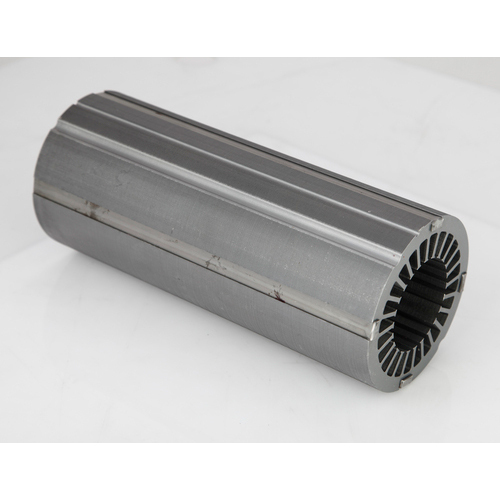

- Interlocked or Riveted

- Round / Slotted / Customized

- Precision stamping, progressive die tooling

- 0.35mm / 0.50mm / 0.65mm

PMDC Motor Rotor Stampings Product Specifications

- 65g to 400g (as per size)

- Silver Grey

- Phosphated / Oiled

- CRNGO / CRGO Electrical Steel

- Dia 18mm 100mm

- 12V / 24V DC

- Rotor Stamping for PMDC Motors

- Custom as per motor design

- Up to 500W (Depends on application)

- As per motor armature design

- Carton box or customized

- Automobile, Home Appliance, Industrial Motors

- Interlocked or Riveted

- Round / Slotted / Customized

- Precision stamping, progressive die tooling

- 0.35mm / 0.50mm / 0.65mm

PMDC Motor Rotor Stampings Trade Information

- 500-800 Ton Per Month

- 15 Days

- Contact us for information regarding our sample policy

- All India

Product Description

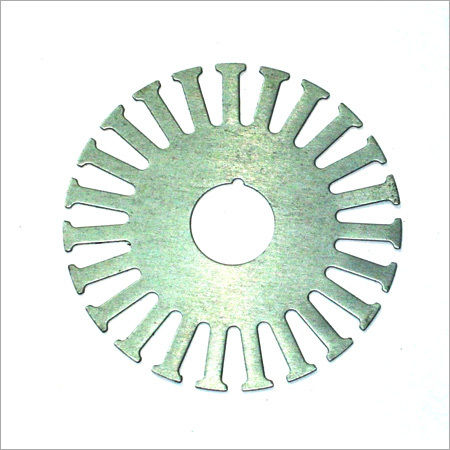

PMDC Motor Stamping Outer Diameter: 60. 30 MM Inner Diameter: 12. 530 MM Slots: 22 Nos. We are reckoned as a one of the distinguished manufacturers, traders, exporters and suppliers of quality approved Alternator Electrical Stamping. This stamping is fabricated using high grade raw materials acquired from trusted vendors of the market. Our offered Alternator Electrical Stamping is broadly known for robust construction, corrosion resistance, high tensile strength, easy installation and elevated service life. Considering the broad needs of the clients, we offer this product in various specifications at an acceptable price range.Precision Stamping for Maximum Efficiency

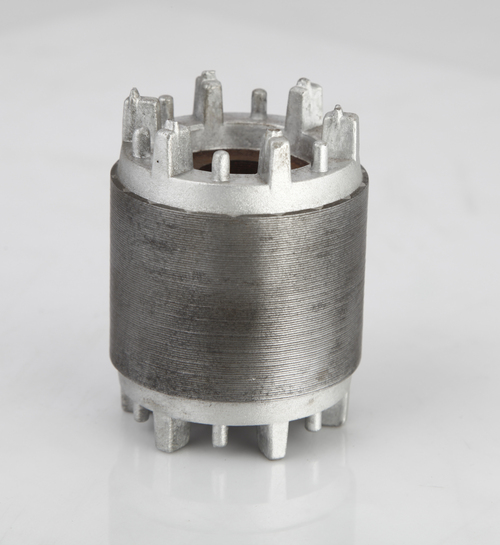

Our PMDC Motor Rotor Stampings are created using state-of-the-art progressive die tooling, ensuring each piece conforms to exacting standards. This high-precision approach contributes to improved motor efficiency and reduces losses in application, making them reliable for a variety of uses.

Versatile Customization Options

Select from multiple thicknesses, shapes, and lamination types to match your design specifications. We offer customized hole arrangements and dimensions, allowing you to integrate the stampings seamlessly with any motor armature design, whether for home appliances, automobiles, or industrial motors.

Quality Materials and Surface Treatment

Manufactured from premium CRNGO and CRGO electrical steel, our rotor stampings provide optimal magnetic performance. Enhanced with advanced surface treatments like phosphating or oiling, these components maintain durability and resist corrosion, ensuring sustained operation under diverse conditions.

FAQs of PMDC Motor Rotor Stampings:

Q: How are PMDC Motor Rotor Stampings manufactured?

A: These stampings are produced using a precision stamping process with progressive die tooling. This method guarantees consistent quality, accurate thickness, and tailored shapes or holes to fit varied motor applications.Q: What materials are used in the production of rotor stampings?

A: We use high-grade CRNGO or CRGO electrical steel, chosen for their excellent electromagnetic properties, to ensure enhanced performance and longevity in demanding motor applications.Q: When should I consider customized shapes or dimensions for my rotor stampings?

A: Customized shapes and dimensions are recommended when your motor design requires specific hole patterns, sizes, or integration featuresnotably in specialized automotive or industrial equipment.Q: Where can these rotor stampings be used?

A: PMDC motor rotor stampings are ideal for applications in automobiles, home appliances, and industrial motors, aligning with varying voltage, power, and dimensional standards.Q: What is the typical process for ordering and delivery?

A: Orders can be placed through dealers, distributors, exporters, manufacturers, retailers, suppliers, or wholesalers across India. Packing is usually done in carton boxes or as per customer specifications, ensuring safe delivery.Q: How does the surface treatment benefit the rotor stampings?

A: Surface treatments such as phosphating or oiling protect the stampings from corrosion and environmental damage, thereby extending their operational life and maintaining motor efficiency.Q: What are the benefits of using these rotor stampings in motors?

A: These rotor stampings offer precise fit, high durability, and optimized magnetic performance for motors, resulting in improved efficiency, reduced power losses, and reliable operation in diverse environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email