Call Us : 08045801213

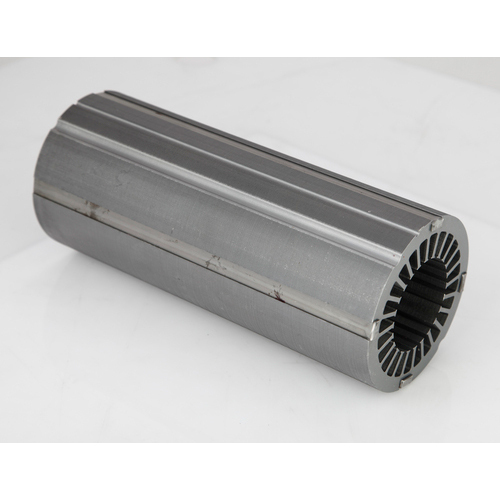

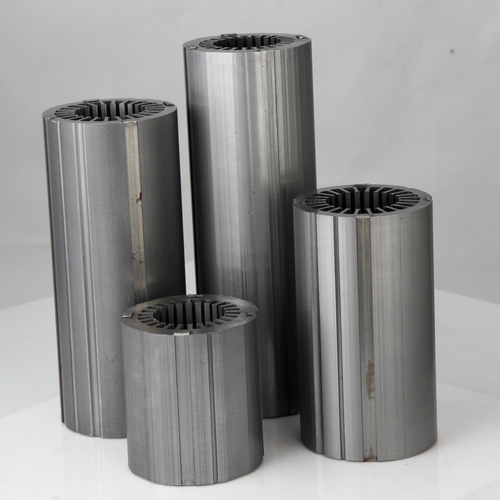

Monoblock Motor Stamping

Product Details:

- Product Type Motor Stamping

- Material CRNO (Cold Rolled Non-Oriented Steel)

- Surface Treatment Zinc/Chrome Plated or as required

- Voltage 220-440 V

- Gross Power Up to 10 HP

- Working Stroke Precision Stamped

- Size Standard and customized sizes available

- Click to View more

X

Monoblock Motor Stamping Price And Quantity

- 1 Ton

- 0.35 mm to 0.65 mm

- High-Speed Stamping Press

- High Dimensional Accuracy

- Carton/Box

- Round and Segmental

- Epoxy Coated (Optional)

- Electric Motors, Monoblock Pumps

- Anti-Rust Coating

- Yes

- Used for Rotor and Stator in Monoblock Pumps and Motors

Monoblock Motor Stamping Product Specifications

- Standard and customized sizes available

- Up to 10 HP

- 220-440 V

- Metallic Grey

- CRNO (Cold Rolled Non-Oriented Steel)

- Customized as per requirement

- Zinc/Chrome Plated or as required

- Precision Stamped

- Motor Stamping

- Depends on size and design

- 0.35 mm to 0.65 mm

- High-Speed Stamping Press

- High Dimensional Accuracy

- Carton/Box

- Round and Segmental

- Epoxy Coated (Optional)

- Electric Motors, Monoblock Pumps

- Anti-Rust Coating

- Yes

- Used for Rotor and Stator in Monoblock Pumps and Motors

Monoblock Motor Stamping Trade Information

- 500-800 Ton Per Month

- 15 Days

Product Description

Find the paragon of engineering excellence with our Monoblock Motor Stampingyour top choice for hot deals in mechanical innovation. Crafted from superb CRNO (Cold Rolled Non-Oriented Steel), these stampings are available in round and segmental shapes, with thickness ranging from 0.35 mm to 0.65 mm. Designed for use in electric motors and monoblock pumps, they ensure unparalleled corrosion resistance and high dimensional accuracy. Choose from anti-rust or epoxy-coated finishes, customized sizes, and efficient packaging. Experience the unmatched performance and reliability trusted by dealers, exporters, and manufacturers across India.

Outstanding Material and Multi-Application Use

Monoblock Motor Stampings are precision-engineered from high-grade CRNO steel, renowned for its anti-corrosive properties and durability. These superb components are tailored for use in both rotor and stator applications within electric motors and monoblock pumps. Suitable for industrial plants requiring high efficiency, they offer versatility with various shapes, sizes, and finishes, making them a primary choice for high-performance machinery installations.

Flexible Payment, Certified Quality, and Secure Shipping

Clients can benefit from competitive list prices, flexible payment terms, and secure packaging options such as carton or box for safe transport services. Each batch carries relevant certifications to attest to their top-notch quality. Customers are informed about product arrival and transit details, ensuring transparency and satisfaction. Trust in certified manufacturing and reliable shipping, whether you are a retailer, wholesaler, or exporter.

Outstanding Material and Multi-Application Use

Monoblock Motor Stampings are precision-engineered from high-grade CRNO steel, renowned for its anti-corrosive properties and durability. These superb components are tailored for use in both rotor and stator applications within electric motors and monoblock pumps. Suitable for industrial plants requiring high efficiency, they offer versatility with various shapes, sizes, and finishes, making them a primary choice for high-performance machinery installations.

Flexible Payment, Certified Quality, and Secure Shipping

Clients can benefit from competitive list prices, flexible payment terms, and secure packaging options such as carton or box for safe transport services. Each batch carries relevant certifications to attest to their top-notch quality. Customers are informed about product arrival and transit details, ensuring transparency and satisfaction. Trust in certified manufacturing and reliable shipping, whether you are a retailer, wholesaler, or exporter.

FAQs of Monoblock Motor Stamping:

Q: How does the anti-rust coating benefit the longevity of Monoblock Motor Stampings?

A: The anti-rust coating provides an effective barrier against corrosion, enhancing the lifespan of the stampings and ensuring sustained performance in demanding operational environments.Q: What are the main applications of these Monoblock Motor Stampings?

A: They are primarily used in rotor and stator assemblies of electric motors and monoblock pumps across various industrial applications.Q: Where are Monoblock Motor Stampings manufactured and shipped from?

A: These stampings are produced using high-speed stamping presses in certified facilities in India and are shipped nationally and internationally.Q: What is the process for customizing size and dimensions for specific project needs?

A: You can provide your required measurements and design specifications during the ordering process, and the manufacturing team will produce samples or series according to those custom requirements.Q: How do I arrange payment and track the arrival of my order?

A: Flexible payment terms are available. Once confirmed, details on transport services and estimated arrival dates will be provided to keep you updated throughout the shipping process.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email