Call Us : 08045801213

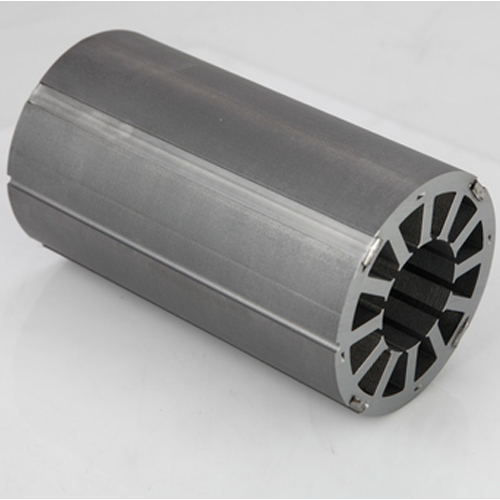

Electrical Stamping

Product Details:

X

Electrical Stamping Price And Quantity

- 1 Ton

Electrical Stamping Trade Information

- 500-800 Ton Per Month

- 15 Days

Product Description

Electrical stamping, also known as laminations or laminated cores, refers to the process of manufacturing thin, flat pieces of metal that are used in various electrical devices and equipment. These stampings are typically made of high-quality electrical steel and are precisely cut and stacked to form the core of transformers, motors, generators, and other electromagnetic devices. Electrical stampings play a crucial role in enhancing the efficiency, performance, and reliability of these electrical components.

Frequently Asked Questions :

Q: What are electrical stampings?

A: Electrical stampings are thin, flat pieces of metal, usually made of electrical steel, that are used in electrical devices such as transformers, motors, and generators. They are cut and stacked to form the core of these devices, providing a path for magnetic flux and reducing energy losses.

Q: What is the purpose of electrical stampings?

A: The primary purpose of electrical stampings is to improve the efficiency and performance of electromagnetic devices. By using laminated cores, which are made up of stacked stampings with insulating layers in between, the formation of eddy currents is minimized, reducing energy losses and enhancing the device's overall efficiency.

Q: Why are electrical stampings laminated?

A: Electrical stampings are laminated to reduce eddy currents, which are induced circular currents that can cause energy losses and generate heat. By laminating the stampings, the magnetic fields within the device are confined to individual laminations, preventing the flow of eddy currents and minimizing energy losses.

Q: What are the typical applications of electrical stampings?

A: Electrical stampings are used in a wide range of applications, including power transformers, electric motors, generators, inductors, and other electromagnetic devices. They are essential in industries such as power generation, transmission and distribution, automotive, aerospace, and consumer electronics.

Q: How are electrical stampings manufactured?

A: Electrical stampings are manufactured through a process known as die stamping or progressive die stamping. This involves feeding a continuous strip of electrical steel through a series of dies that progressively cut and shape the stampings. The stampings are then separated, cleaned, and further processed as per the specific requirements of the application.

Enter Buying Requirement Details

Call Me Free

Call Me Free